Geared motor,Moto Reducteur,Motor reducer,Reducer Motor

Geared motor,Moto Reducteur,Motor reducer,Reducer Motor

BOSERL

BOSERL Gearbox Manufacturer operates with German-imported production lines, a comprehensive German quality management system, and advanced German technology. It features full-spectrum product R&D testing alongside automated, information-driven manufacturing operations.

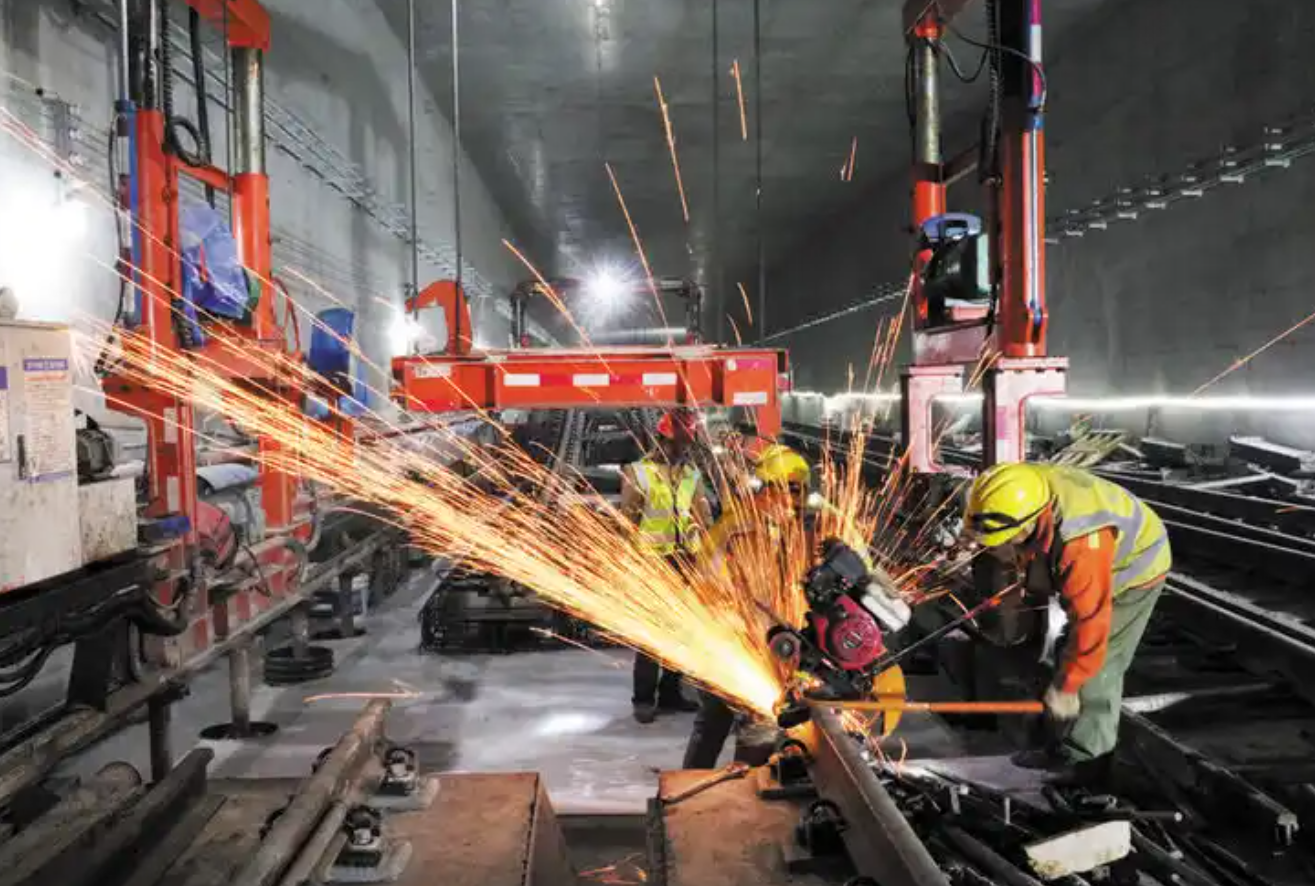

The production base for gearmotors spans 17,000 square meters, with an annual output value exceeding 700 million yuan. subway tunnels, mixing tanks, stage machinery, cranes, winches, positioners, hydraulic motor reducers, and other industries.

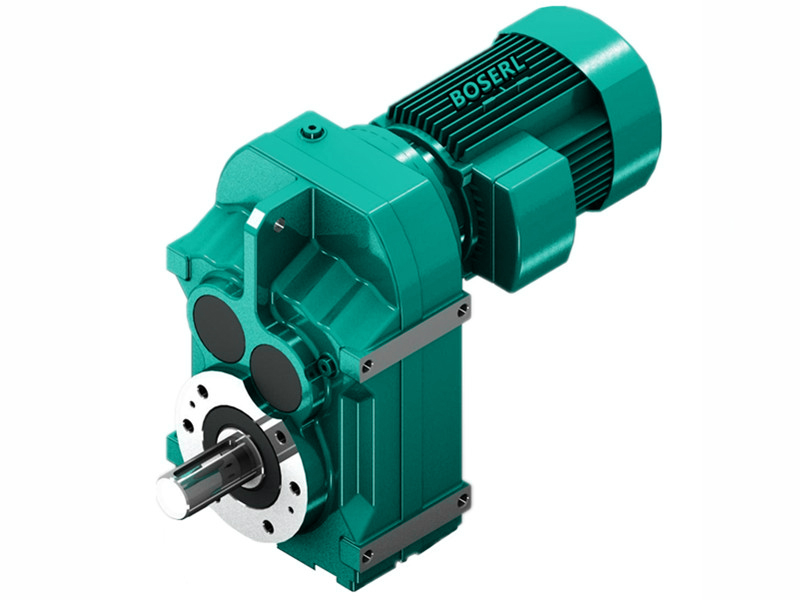

Imported technology from Germany ensures the high efficiency and performance of BOSERL gear reducer products.

BOSERL continuously optimizes production metrics, and the relentless pioneering spirit of its workforce establish BOSERL's premium quality.

Experienced engineers provide one-on-one selection services, ensuring zero errors when customers choose reducer models.

Our direct-from-manufacturer sales model for motorized gear reducers eliminates middlemen, passing savings directly to end customers for premium quality at competitive prices

<span style="color: rgb(0, 0, 0);" BOSERL motorized gear reducers consistently lead the industry in quality control and production technology. Integrated R&D, testing, and manufacturing streamline procurement and reduce costs.

Hydraulic transmission reducers, hoist reducers, slewing reducers, travel reducers, right-angle reducers, servo motor reducers, reducer frames, and various other reducer series meet your needs

<span style="color: rgb(0, 0, 0);" BOSERL gear reducer engineers provide 24/7 service, offering 2D and 3D drawings for all gear reducer series. BOSERL gear reducer manufacturers deliver timely and punctual service.

(c) stage mechanical power-carrying brake application. What is often required in stage lifts and landings is the promotion of pedals on stage to specified heights or to reverse, for example, through electro-deployed speed reduction boxes and other assistive devices. At this point, the motor decelerator will need to operate at a rate of 20 centimetres per second by its own power and will need to be adjusted according to actual needs. How do we adjust? How do we change the speed of the k87? the speed ratio of the often slow-down machines after the purchase of a k87 is certain

View more

A mixer can with an electric brake application. The main axle of the mixer, which is installed on the main axle of the mixer, is directly driven by the output axle of the motor decelerator. The more finer the feed, the longer the motor-reducing box runs. So how do you make the feed? The feed mixer is one of the feed makers that mixs the different ingredients. How can the market demand for meat products be met? In addition to the entry point, there is another way to feed. I'm going to tell you how this structure worked in the course of work and how it was managed to maintain these devices later in use

View more

(c) High-iron orbital-band decelerator electric power application. The high-wire trajectories, which also need to be accompanied by a speed-retarder, determine that a K-series speed-retarder would be more appropriate, and ultimately a K-series screw-conut gear-retarder. The option has a special requirement: it is to be used at low temperatures in the Harbin high iron orbit at minus 40°C. Frozen, low-temperature oils are used at ambient temperatures -40 ~50 °C and at low temperatures. After double-counting parameters by Engineering, the client is advised not to use a low-speed machine, but to use our regular 1400rpm

View more

The subway tunnel station was equipped with a speed-reducing power application. Subway Tunnel Test Station with Speed Detachor Electrical Option. Used at Shenzhen Subway Station to detect subway vans. The work machine was hung with a mechanical arm, and the subway carriage was then made easier for engineers to detect some of the devices inside the subway. The motors with the brakes are mounted on a half-air mechanical arm device, which needs to be mounted and installed with very good quality. Because of the heavy weight of the subway, the length of the subway section is 22mX by 3.0mX by 3.8m and weighs about 12 tons, while the metro on this line is, in six sections, a two-axis shift

View more

Contact us

Guangdong Boshi Transmission Technology Co., Ltd.

Contact: Mr. Zhang

Mobile: +86 13360667204 (also WeChat ID)

Email: [email protected]

Address: Xiedi Industrial Zone, Wanjiang District, Dongguan City, Guangdong Province

ATTENTION

Quick Navigation